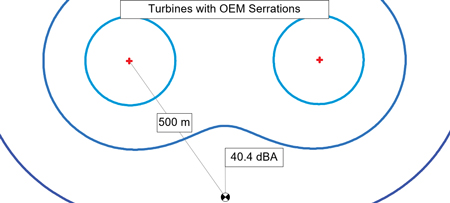

Flexible Serrations Help Lower Low-Frequency Noise While Maintaining Turbine Performance

The issue of wind turbine noise has become a pressing topic in recent years in many areas around the world, especially in Europe. The development of new wind power facilities balances the pursuit of open development areas with optimal wind resources with the practicality of grid connection by situating these facilities closer to areas of higher population. These two drivers are often in tension, and this has led to the development of projects with operation in noise-reduced modes, sacrificing power in the process. This is standard practice in the industry today. Aerodynamic noise has continued to increase as rotor sizes and rated power increases. Although serrated trailing edges have been around for many years in the wind industry to combat this increase in noise, innovation has stalled. At present, serrations deliver around 2dB(A) reductions from a bare blade, yet the situation of noise curtailment remains. Further, these technologies do not typically alter aerodynamic performance, although in practice they have been known to reduce it. As such, there is a desire for technologies that can reduce noise even further without sacrificing aerodynamic performance. The FeatherEdge technology offers a promising advancement in this area, delivering both a noise and power benefit, specifically targeting the low-frequency bands.

The issue of wind turbine noise has become a pressing topic in recent years in many areas around the world, especially in Europe. The development of new wind power facilities balances the pursuit of open development areas with optimal wind resources with the practicality of grid connection by situating these facilities closer to areas of higher population. These two drivers are often in tension, and this has led to the development of projects with operation in noise-reduced modes, sacrificing power in the process. This is standard practice in the industry today. Aerodynamic noise has continued to increase as rotor sizes and rated power increases. Although serrated trailing edges have been around for many years in the wind industry to combat this increase in noise, innovation has stalled. At present, serrations deliver around 2dB(A) reductions from a bare blade, yet the situation of noise curtailment remains. Further, these technologies do not typically alter aerodynamic performance, although in practice they have been known to reduce it. As such, there is a desire for technologies that can reduce noise even further without sacrificing aerodynamic performance. The FeatherEdge technology offers a promising advancement in this area, delivering both a noise and power benefit, specifically targeting the low-frequency bands.

By Ryan Church, CEO, Biome Renewables, Canada